Students in a Manufacturing, Transportation and Industrial Technology pathway prepare for careers in highly technical environments working with various machinery and equipment. Possible careers in this school of study include HVAC technician, auto body repair technician, automotive technician, corrosion technician, heavy equipment technician, industrial maintenance technician, instrumentation technician, safety and health inspector, plant operator, process technician, and welder.

This program prepares students as entry-level service technicians in the heating, ventilation, air conditioning and refrigeration fields. Students who graduate from this program can install, maintain and repair equipment and accessory units for commercial, residential and industrial usage. Students also study the repair of home appliances, such as ice makers, window air conditioners, freezers and refrigerators.

Kilgore offers one the best programs in the nation for serious students interested in a career in automotive repair. KC’s NATEF and ASE certified program is the only one of its kind in East Texas and is designed to teach the basic automotive theories and tasks related to all ASE Certification areas. A lecture/lab format gives students hands-on experience. All automotive courses are taught by ASE certified instructors.

Corrosion is a costly problem for the US, with over $300 billion in yearly expenses and serious consequences for safety, the environment, and finances. Government agencies require corrosion control, and it involves utilizing various sciences such as metallurgy and chemistry. Those studying Corrosion Technology may qualify for departmental scholarships from companies and individuals.

The Diesel Technology program prepares students for positions in the exciting world of HD diesel truck repair as well as construction, agricultural and stationary diesel equipment repair. Local shops employ students as part-time technicians while attending classes. Students are instructed in fuel systems, electrical and electronic testing and repair, as well as hydraulics, brakes, air-conditioning and powertrains. Students can graduate with ASE certifications, MACS certifications, safety and Haz-Mat certifications.

The Industrial Maintenance Technology Program prepares students for careers in large manufacturing companies as industrial machinery and maintenance technicians. Industrial maintenance technicians keep plant machinery and equipment up-and-running so that production can continue. The program consists of two certificates and an associate of applied science degree. Both certificates and the associate’s degree have cooperative courses, in which students will receive actual on-the-job training.

The Manufacturing Technologies program at KC prepares students for careers in manufacturing with a focus on mechanical, electrical, machining and automation. Degrees/certificates offered include a Manufacturing Technology (Associate of Applied Science) and two certificate programs: (Manufacturing Certificate-Machining and Manufacturing Certificate-Mechanical/Electrical).

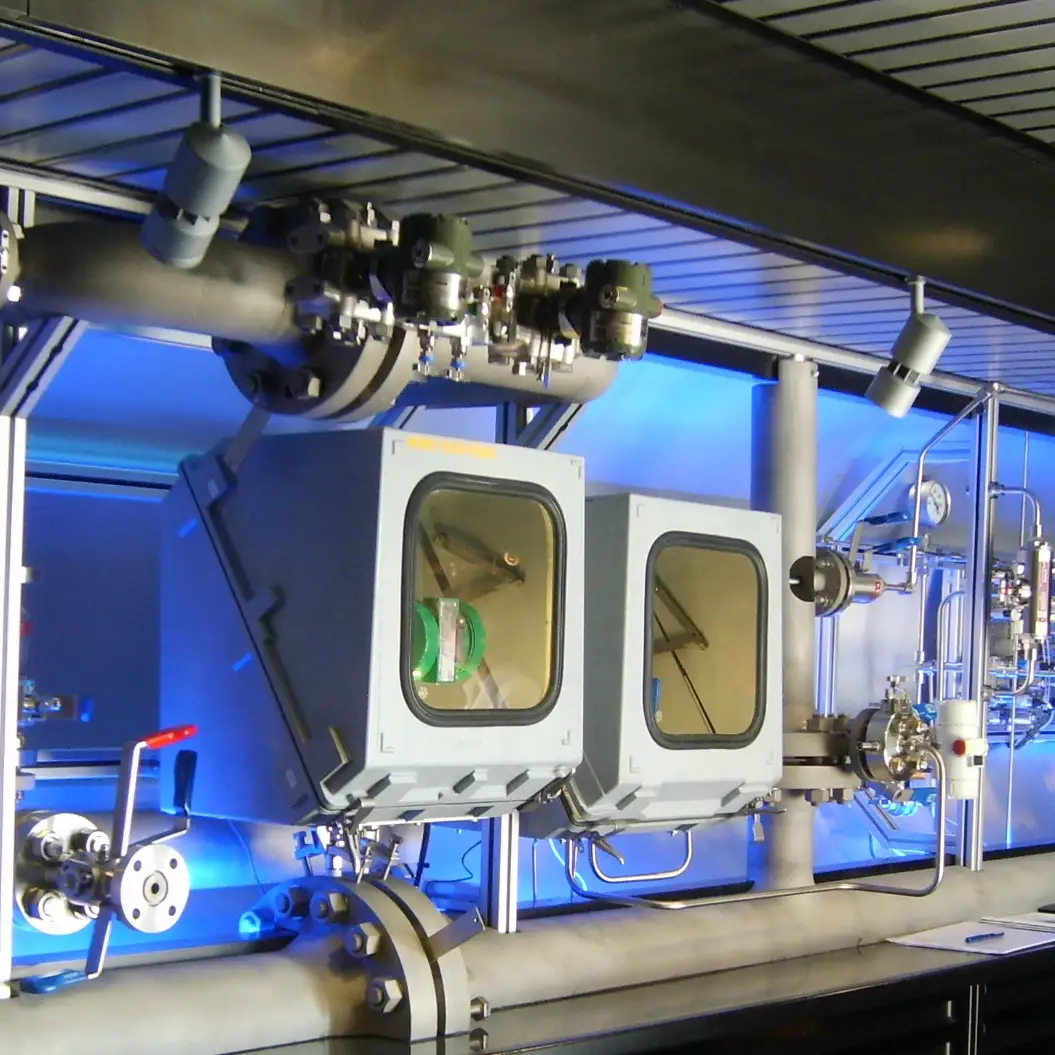

Many industrial firms now use automation practices which require highly programmed electronic equipment to do work that used to be performed by people. Due to their complicated nature, automated devices frequently run into problems which electrical instrumentation technicians must solve. Electrical instrumentation technicians troubleshoot, repair and maintain the various parts needed to keep automated machinery running smoothly and effectively. A degree or certificate is usually necessary to land work as an electrical instrumentation technician.

The program prepares you for a career in the growing field of Occupational Safety and Health. The code of Federal Regulations (CFR) for the Occupational Safety and Health Administration (OSHA), Environmental Protection Agency (EPA), and the Department of Transportation (DOT) are examined as well as safety regulations of the construction industry. This program provides you with information and training necessary to create a safe work environment and maintain compliance with state and federal regulatory agencies.

Process Technology is an environment of teams of people responsible for planning, analyzing, and controlling the production of products from the acquisition of raw materials through the production and distribution of products to customers in a variety of process industries.

The ability to understand, operate, shut down, analyze and troubleshoot petroleum-related processes. Petroleum process technicians are key to the production, operation, and distribution of petroleum products in East Texas and in other petroleum-producing parts of the U.S. This program includes the opportunity for practical experiences. This program is recognized by the Texas Workforce Investment Council (TWIC).

Welding is the most common way of permanently joining metal parts. Heat is applied to the pieces to be joined, melting and fusing them to form a permanent bond. Because of its strength, welding is used to construct and repair ships, automobiles, spacecraft, and thousands of other manufactured products, and to join beams when constructing bridges, buildings and other structures. Starting pay for graduates is up to $24 per hour in the East Texas area.